Overview

Orders represent formal commitments between buyers and sellers for future delivery of goods or services. Sales orders capture customer commitments to purchase from your business, while purchase orders document your commitments to buy from suppliers. They specify products or services, quantities, agreed prices, delivery terms, and expected fulfillment dates. Orders create binding commercial agreements, establish delivery expectations, enable inventory planning and procurement workflows, and serve as the foundation for subsequent invoicing and fulfillment processes.Components of Sales Orders

- Order Header: containing basic order information like order number, order date, requested delivery date, customer reference, and payment terms

- Customer Information: including billing address, shipping address, contact details, and customer ID/reference number

- Line Items: capture individual products/services ordered, including item description, quantity, unit price, agreed pricing, and line totals

- **Pricing and Discounts: ** for each line item and order totals, including special pricing, volume discounts, and promotional codes

- Totals Section: show subtotal, estimated tax amount, shipping costs, discounts applied, and total order value

- Delivery Information: including shipping method, delivery address, requested delivery date, and special delivery instructions

- Order Status: tracking order lifecycle from pending through confirmed, in-production, shipped, and delivered

Components of Purchase Orders

- Order Header: with purchase order number, order date, requested delivery date, and supplier reference

- Supplier/Vendor Information: including vendor details, delivery address, contact information, and vendor ID

- Line Items: capturing ordered goods/services with item codes, descriptions, quantities, agreed unit costs, and line totals

- Delivery Terms: including shipping method, delivery location, lead times, and delivery instructions

- Cost Centers or Projects: for budget allocation and expense tracking purposes

- Approval Workflow data showing who approved the purchase order and any authorization codes

- Totals Section: with subtotal, estimated tax amounts, shipping/handling fees, and total order value

- Order Status: tracking from draft through approved, sent to vendor, acknowledged, and delivered

Key Differences from Invoices

Unlike invoices which represent demands for payment, orders represent commitments for future performance. Orders typically do not create immediate accounting entries but instead establish commitments that will be fulfilled through delivery and subsequent invoicing. Many systems track order commitments separately from actual financial transactions until goods are delivered or services are performed.Building Your First Integration

Select the appropriate drop-down below based on which Alloy Automation product you’ll be building with.Embedded iPaaS

Embedded iPaaS

1. Choose a Platform to Integrate with

Popular accounting and enterprise resource planning (ERP) tools include SAP S/4HANA, Oracle NetSuite, Xero, Intuit Quickbooks, and Microsoft Dynamics Business Central. You can either create an integration purely for purchase and sales orders or add these workflows to your existing integration.2. Capture Global Account Values With On-Installation Workflows

Account Variables are global variables, accessible to all Workflows within an integration, but specific to a user installation. We recommend using Account Variables to collect account-level information that will be used when creating new orders. For example, you may want to use Account Variables to capture Account IDs, default currency codes, order number prefixes, default shipping methods, and standard delivery terms, among others.When deciding what values to save as Account Variables, ask yourself, “What values do I want to apply as defaults to all Sales and/or Purchase orders?” We always recommend creating a dedicated workflow that captures these Account Variables, using the On Installation Trigger to ensure that these values are set immediately upon installation.3. Send New Sales & Purchase Orders to Alloy in Real-Time

New sales and purchase orders can be retrieved from either a Custom Event or Polling Endpoint. We typically recommend invoking an Alloy Custom Event to send real-time orders to Alloy as they’re created in your platform.Below are two examples of Customer Events – one sales order, one purchase order – that you can use to trigger real-time Workflow that sends new orders to an ERP of your choice.Sales Order Sample Payload

Sales Order Sample Payload

Purchase Order Sample Payload

Purchase Order Sample Payload

4. Read/Create Customers & Vendors

One critical step that differentiates Orders from Journal Entries is the need to associate Sales Orders with customers and Purchase Orders with Vendors. As part of the Order creation workflow we recommend first, using an email or other identifying information in the originating Order payload to attempt to lookup an existing customer or vendor from the ERP connector. If one exists, you can use the returned ID in the Customer ID or Vendor ID field in the ERP connector action where you’re creating the Order. ERP connectors like Business Central, Quickbooks and others expect internal IDs to be used in these fields.You can use an if-else block to determine if a valid customer or vendor is returned and create a new one if not.5. Add Sales & Purchase Order Line Items

Once the order is created you’ll need to also add line items. Some connectors like Microsoft Dynamics Business Central will provide a separate action to add line items while other connectors will nest line items within the Create Purchase Order or Create Sales Order action.If line items are created in separate step you can first create the parent order with a dedicated connector action. From there you can use an iterate node to loop through the line items from the originating order payload and create individual line items associated with the parent order. Check out one of the video walkthroughs below to see how to accomplish this.In some cases your order line items will need to reference actual internal Item IDs in your ERP instance. In some platforms like Microsoft Dynamics Business Central you can, instead, reference G/L accounts instead of Items if you do not need to do physical inventory tracking. For orders, you may also need to check item availability and lead times before confirming order quantities.

6. Map Fields from the Custom Event to ERP Connector Fields

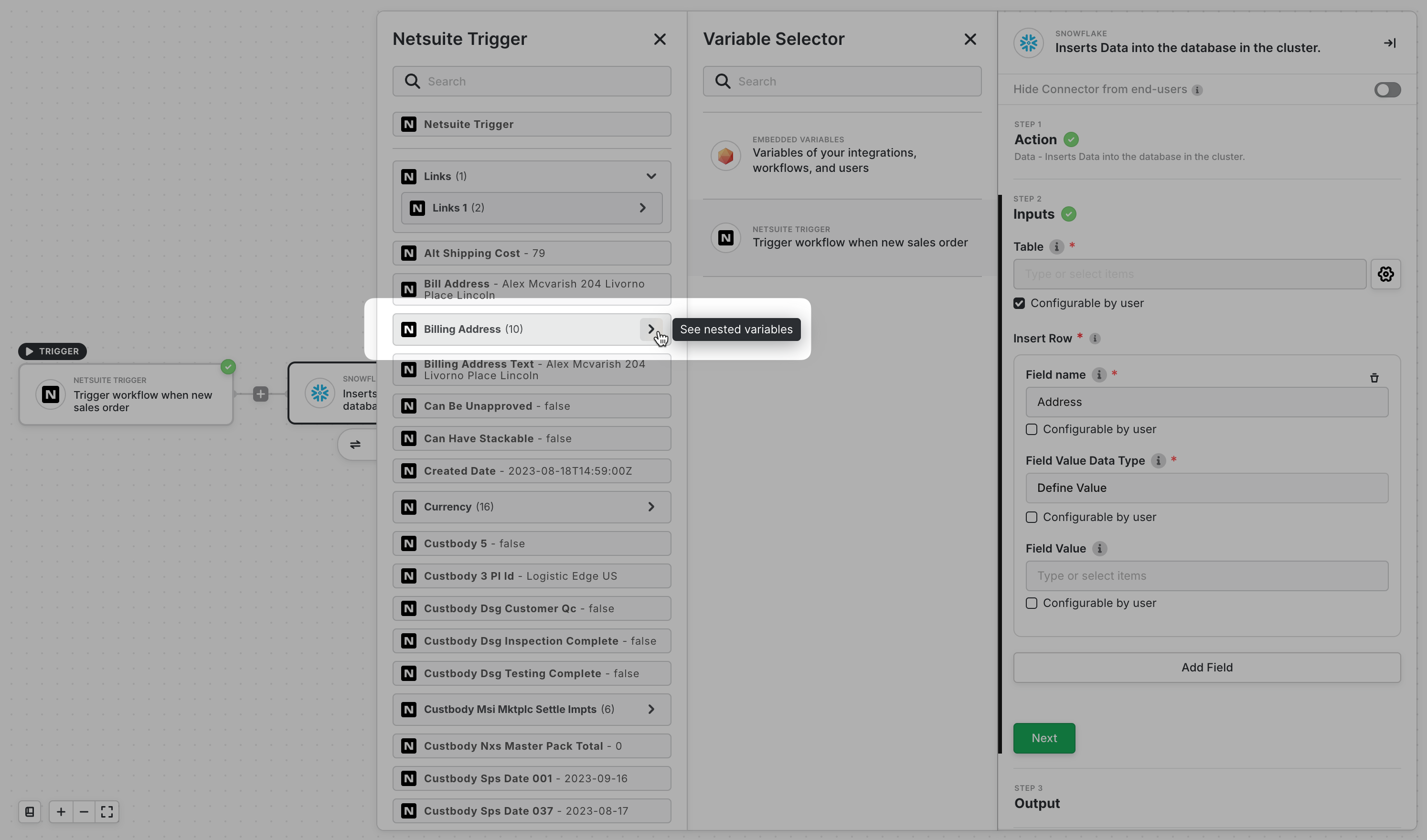

The last step in the configuration process is to map the fields from the order Custom Event payload to the input fields in the Connector Action. This can be accomplished easily by selecting the relevant action (e.g. Create New Sales Order) and using the point-and-click interface to add the relevant values to each input field

7. Handle Order Status Updates and Lifecycle Management

Unlike invoices which are primarily creation-focused, orders require ongoing status management throughout their lifecycle. Consider implementing additional workflows to handle:- Order Confirmations when customers or vendors acknowledge receipt

- Status Updates as orders move through fulfillment stages

- Delivery Confirmations when goods are shipped or services are delivered

- Order Modifications for quantity changes, delivery date updates, or cancellations

8. Deploy the Integration

Once your integration is built and tested you can begin sharing it with your end-users. We have several methods for deploying and sharing your integrations, which you can read more about in our documentation.Video Walkthrough Library

We’ve created video walkthroughs for the most common and complex integration scenarios. Choose a walkthrough below to build alongside our experts. We regularly add new videos, so check back for updates!Creating Purchase Orders in Business Central (Coming Soon)

Creating Purchase Orders in Business Central (Coming Soon)

Connectivity API (Coming Soon)

Connectivity API (Coming Soon)

MCP Gateway (Coming Soon)

MCP Gateway (Coming Soon)